Background

Rapid prototyping and rapid tooling are essential tools used for mass customisation manufacturing. The prototype gives the customer a complete idea of what their product will ultimately look like. Rapid prototyping relies on plastics, powders and metals and has a sever environmental impact. 3D printing has been a revolution in manufacturing and an opportunity for dramatic environmental improvement. Prototyping allows designers to streamline the development process. We can use 3D printed food in the first stage prototyping process. Not only does it consume less resource and generates less (no) waste but also allows your fascinated client to immerse themselves in the production process. The cocoa desk demonstrates unending potential for the use of food printing and prototype production.

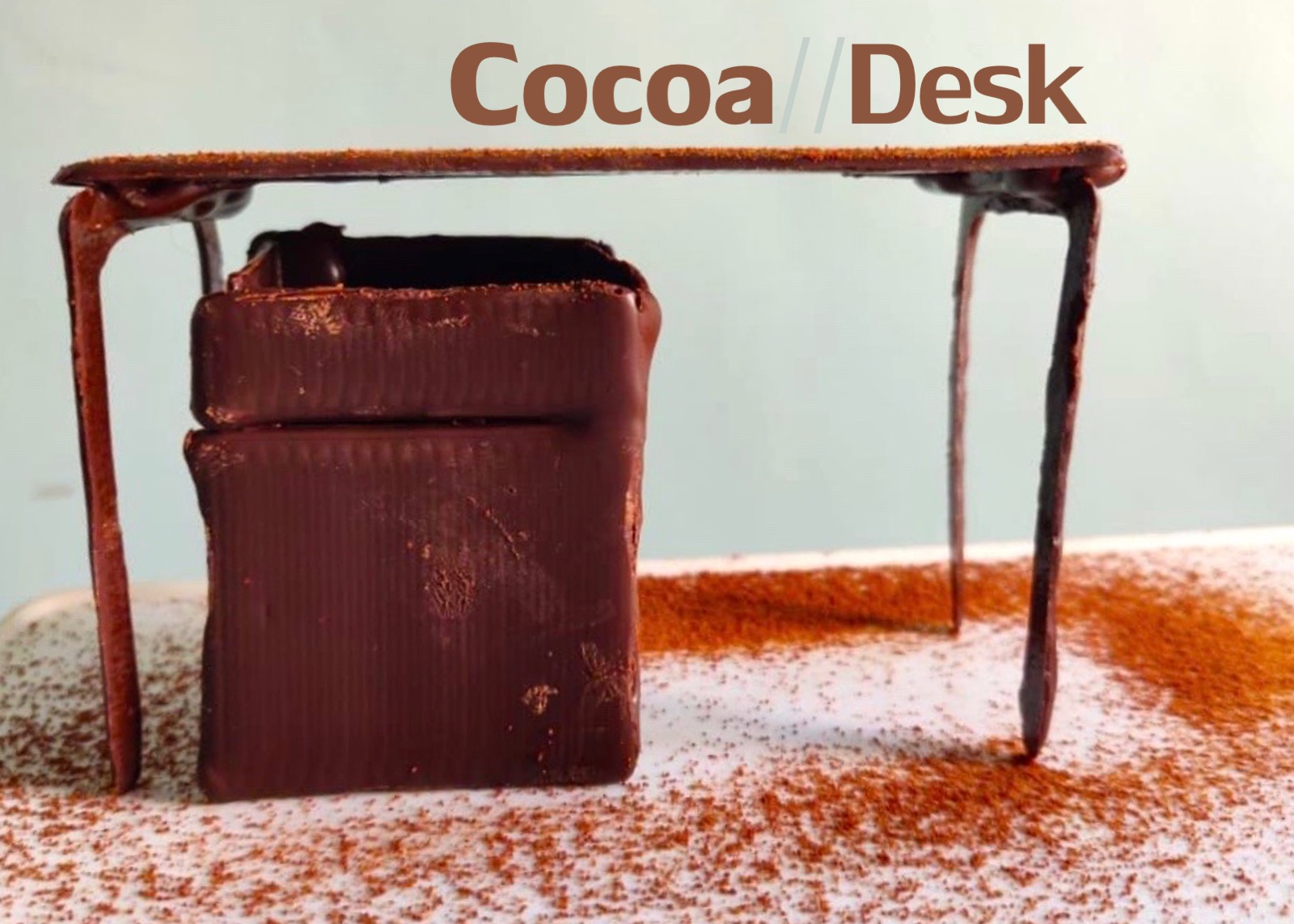

Cocoa Desk

Mumbai-based REIN Design Studio created a sleek piece of furniture, the Cocoa Desk. As the inspiration for the design came from cocoa pods, chocolate was an ideal option for prototyping. The uniform material, deep colour, striated texture and deep aromatic flavour complements the product. Chocolate is also a more economical, sustainable and (most importantly) edible option at this early stage of development. We work on the scaled 2D drawings to print edible individual surfaces. We then assemble the surfaces together to assess and document the design. After rapidly testing modifications (if any), we celebrate our success by devouring the delicious prototype! No waste, just smiles.

Let’s grab a (virtual) cup of coffee and explore how we can work with you. Contact us.